My Projects

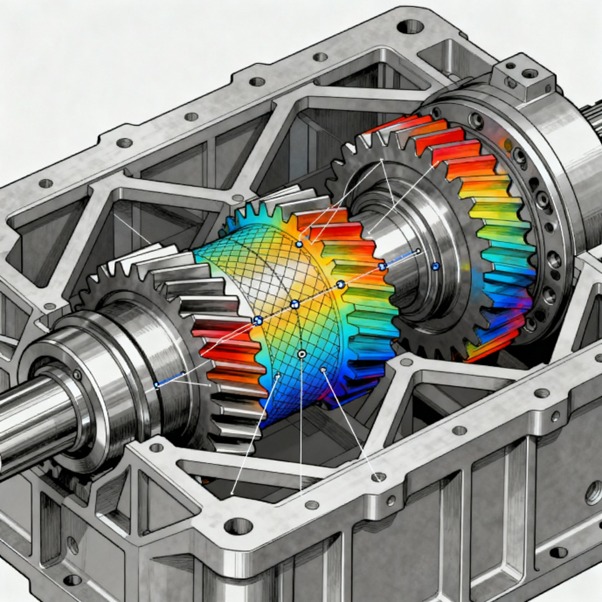

Modal Frequencies of Box Truss Model Gear Box Using Machine Learning

This project focuses on replacing conventional closed-type cast iron gearbox casings with a lightweight mild steel box truss design. The proposed structure aims to reduce material usage, cost, and weight while sustaining vibrations during operation. Structural, modal, and harmonic analyses were performed using ANSYS alongside machine learning techniques to predict deformations and resonance frequencies. Experimental validation with vibration testing confirmed the feasibility of the mild steel truss casing under static and dynamic conditions. The study demonstrates that the new design is safe, economical, and efficient for practical gearbox applications

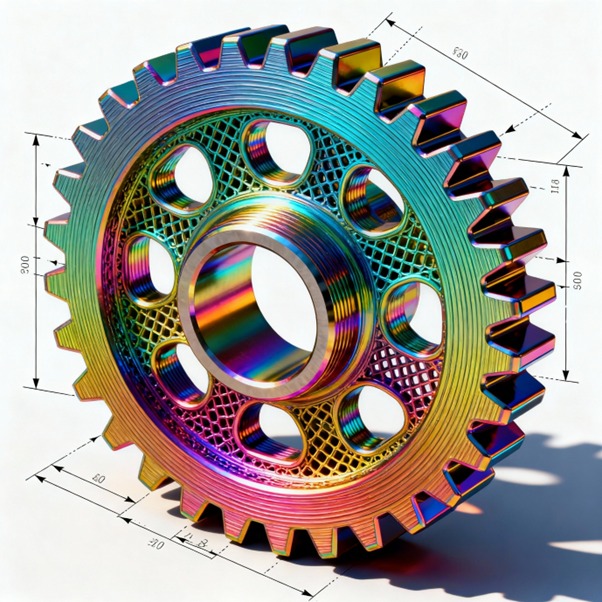

Optimization of FDM Process Parameters for Enhanced Quality of PLA 3D Printed Component

This study investigates the optimization of Fused Deposition Modelling (FDM) process parameters to improve the quality of PLA 3D-printed components. Printing speed, layer thickness, and fill density were selected as key variables, with surface roughness and hardness as performance indicators. Using a Taguchi L9 orthogonal array with ANOVA and MRPI analysis, the optimal parameter set was identified, resulting in a 35% improvement in hardness and 14.7% reduction in surface roughness compared to the initial setup.

Design and Static Structural Analysis of Composite Propeller Shaft-A Comparative Study

This study presents the design and structural analysis of a composite propeller shaft as a lightweight alternative to conventional steel (SM45C) shafts. Carbon/epoxy, boron/epoxy, and E-glass/epoxy were evaluated using classical lamination theory, finite element simulations, and experimental validation for a maximum torque of 400 N-m. Results indicate that carbon/epoxy offers the best balance of strength, torsional rigidity, and weight reduction—achieving nearly 75% lower mass than steel, demonstrating the potential of composites to improve fuel efficiency and payload capacity in automotive applications.